PARTNERSHIPS

Zero Solids Recycling Signals a New Water Play in the Permian

A new water system in the Permian Basin challenges old treatment models by stopping solids before they form, pointing toward a reuse-first future

10 Feb 2026

A shift is under way in the US oil and gas sector as operators grapple with rising volumes of produced water and tighter limits on disposal. In the Permian Basin, a new partnership between WT Oil & Gas and water treatment group EnviroKlean is drawing attention for its attempt to rethink how that water is handled.

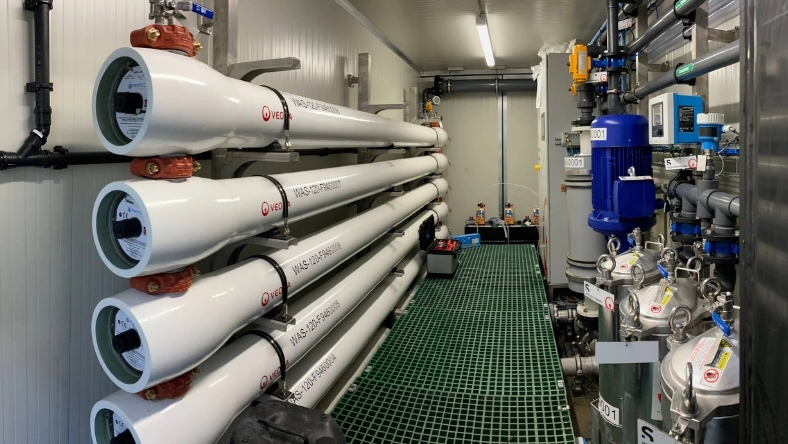

The companies have begun rolling out EnviroKlean’s Zero Solids Recycle system, known as ZSR, which is designed to prevent solids from forming in produced water rather than removing them after the fact. By keeping minerals and contaminants dissolved, the system aims to keep water in a reusable state with less equipment and intervention.

Produced water volumes typically increase as wells mature, making water handling one of the fastest growing cost centres for upstream producers. Traditional treatment often relies on filtration, chemical dosing and frequent maintenance, alongside the transport and disposal of sludge and residual waste. These processes add costs and create additional regulatory and safety concerns.

At the same time, regulators and investors are paying closer attention to how companies manage disposal wells and freshwater use. In arid regions such as west Texas and New Mexico, pressure is mounting to reuse water within operations rather than rely on new supplies or expand disposal capacity.

The ZSR approach reframes produced water as an input to be managed from the outset of field design. WT Oil & Gas contributes operational experience in running large scale water systems, while EnviroKlean provides chemical treatment intended to stabilise contaminants in solution. The companies say this reduces the need for bulky surface equipment and lowers the volume of solid waste requiring transport and disposal.

Fewer solids can also translate into a smaller surface footprint, reduced truck traffic and lower safety risks, alongside potential cost savings. Industry analysts say such integrated systems reflect a broader move away from standalone treatment technologies towards designs centred on reuse.

While the initial focus is the Permian Basin, similar challenges are emerging globally, particularly in water stressed regions where produced water reuse is becoming a strategic priority. Uptake will depend on local geology, regulation and infrastructure, but the underlying pressures are common across major oil and gas basins.

As produced water volumes continue to rise, approaches that prevent waste rather than manage it after formation are likely to play a growing role in how operators control costs and meet environmental expectations.

Latest News

16 Feb 2026

Oilfield Wastewater Finds a Second Life12 Feb 2026

Produced Water Gains New Value in a Thirsty Gulf10 Feb 2026

Zero Solids Recycling Signals a New Water Play in the Permian6 Feb 2026

Water From Air Signals a Cautious Shift Beyond Desalination

Related News

INSIGHTS

16 Feb 2026

Oilfield Wastewater Finds a Second Life

REGULATORY

12 Feb 2026

Produced Water Gains New Value in a Thirsty Gulf

PARTNERSHIPS

10 Feb 2026

Zero Solids Recycling Signals a New Water Play in the Permian

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.