RESEARCH

Water Stress Pushes Oil and Gas to Rethink the Basics

Water scarcity and stricter oversight are driving Middle East energy firms to treat produced water as a strategic asset, not a disposal problem

30 Jan 2026

A quiet shift is underway in the Middle East energy sector, and it starts with water. As freshwater becomes harder to secure and environmental scrutiny sharpens, oil and gas companies are rethinking how they handle produced water. What was once a disposal problem is now emerging as a potential advantage.

Produced water is the water that comes up alongside oil and gas during production. For decades, operators mainly injected it underground or hauled it to centralized treatment sites. Both options are expensive and increasingly difficult to justify in regions already under water stress. Regulators are asking tougher questions, and communities are paying closer attention.

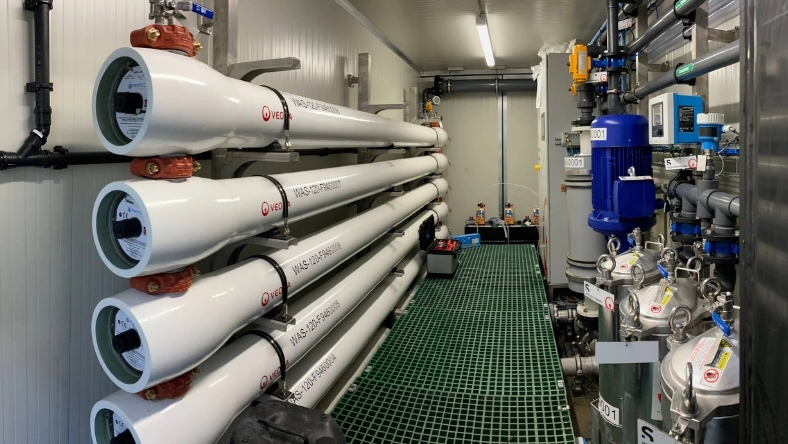

The response has been a growing focus on treating water closer to the wellhead. Modular, site level treatment systems are gaining traction because they allow operators to reuse water for drilling, fracturing, or reservoir support. Treating water on site cuts transport costs and reduces reliance on scarce freshwater supplies.

Technology providers are adapting quickly. Companies like Veolia now emphasize flexible treatment units that can be scaled up or down as production changes. The appeal is not just environmental. These systems offer operators more control over costs and operations in a volatile market.

Service firms are also reframing the conversation. At SLB and others, produced water reuse is increasingly presented as a strategic lever rather than a box ticking exercise. When water planning is built into field development from the start, it can lower risk and improve efficiency, especially as Gulf regulators tighten standards.

“This is no longer just about wastewater,” said a regional energy consultant involved in upstream projects. “It is about resilience. Companies that manage water well are better prepared for regulatory pressure, cost swings, and public scrutiny.”

The hurdles are real. Produced water chemistry varies widely, and not every barrel can be treated to the same standard. Concentrated waste streams still require careful disposal. Operators also need confidence that treatment systems will perform reliably over years, not just during pilot projects.

Still, momentum is building. Conferences, pilot programs, and new contracts all point to rising interest in reuse. As more projects move from trial to routine use, produced water is likely to become central to upstream strategy. In a region where water is as strategic as energy, that shift could change the rules of the game.

Latest News

16 Feb 2026

Oilfield Wastewater Finds a Second Life12 Feb 2026

Produced Water Gains New Value in a Thirsty Gulf10 Feb 2026

Zero Solids Recycling Signals a New Water Play in the Permian6 Feb 2026

Water From Air Signals a Cautious Shift Beyond Desalination

Related News

INSIGHTS

16 Feb 2026

Oilfield Wastewater Finds a Second Life

REGULATORY

12 Feb 2026

Produced Water Gains New Value in a Thirsty Gulf

PARTNERSHIPS

10 Feb 2026

Zero Solids Recycling Signals a New Water Play in the Permian

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.