INNOVATION

From Liability to Lifeline: Rethinking Produced Water in Oilfields

Water scarcity and regulation push oil producers to rethink handling of produced water

12 Dec 2025

A gradual but significant shift is under way across Middle Eastern oilfields as operators reassess how they manage produced water, a by-product long treated as a cost and disposal problem. Rising water volumes, tighter oversight and pressure to protect limited freshwater resources are pushing reuse higher on the agenda.

Produced water reuse is not yet a standard feature of upstream strategy in the region. However, interest in advanced treatment technologies is growing, and water management is increasingly discussed alongside cost control, infrastructure resilience and long-term sustainability. National oil companies, regional producers and technology groups are exploring models that move beyond injection or discharge towards more flexible approaches.

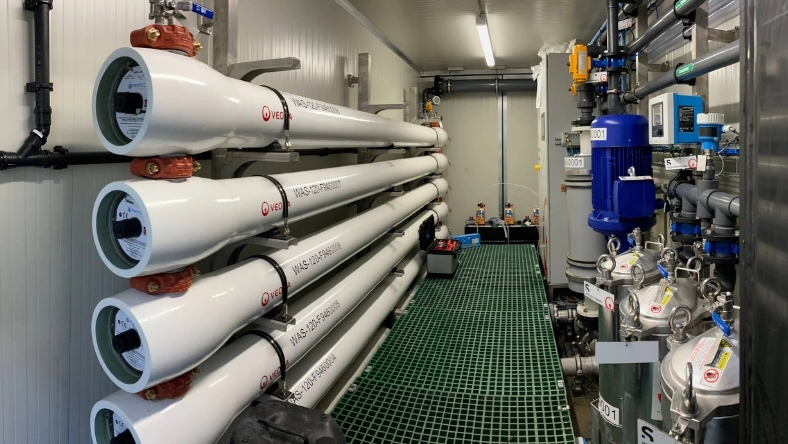

International water technology companies such as Veolia have expanded their presence in the Middle East, offering integrated produced water treatment systems designed to enable reuse in operational activities. These include uses in drilling, enhanced oil recovery and other field operations. The aim is to reduce reliance on freshwater or desalinated supplies while lowering the costs and risks linked to transport, disposal and regulatory compliance.

For many producers, reuse is being positioned as a practical extension of broader water efficiency efforts rather than a radical shift. Large operators have already framed water management as a strategic priority. Abu Dhabi National Oil Company has highlighted water optimisation through partnerships, while Saudi Aramco has emphasised conservation, wastewater reuse and improved water practices across its assets. Analysts say these initiatives align with rising interest in produced water reuse, particularly as regulatory scrutiny increases.

Scale is a key factor. As oilfields mature, water production typically rises faster than hydrocarbon output, putting pressure on infrastructure and compliance systems. Treating and reusing produced water can help ease these constraints and reduce exposure to supply and regulatory risks. Governments across the region are also strengthening oversight of water use and discharge, reinforcing the economic case for reuse.

Barriers remain. Advanced treatment systems require capital investment, technical expertise and consistent operating standards, which vary across markets. Even so, collaboration between operators and technology providers is increasing, helping to spread risk and build operational experience.

As costs fall and familiarity grows, produced water reuse is expected to play a larger role in upstream water management. What was once an operational burden may increasingly be viewed as a strategic asset for operators willing to invest.

Latest News

16 Feb 2026

Oilfield Wastewater Finds a Second Life12 Feb 2026

Produced Water Gains New Value in a Thirsty Gulf10 Feb 2026

Zero Solids Recycling Signals a New Water Play in the Permian6 Feb 2026

Water From Air Signals a Cautious Shift Beyond Desalination

Related News

INSIGHTS

16 Feb 2026

Oilfield Wastewater Finds a Second Life

REGULATORY

12 Feb 2026

Produced Water Gains New Value in a Thirsty Gulf

PARTNERSHIPS

10 Feb 2026

Zero Solids Recycling Signals a New Water Play in the Permian

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.